The first step towards more digitalisation in production began with an analysis process to identify potential improvements in the production workflow. For this, design composite was able to make use of the “Coaching” funding from the state of Salzburg.

More Transparency through New Systems

Building on this, a custom production software tailored to in-house needs was developed in collaboration with a software partner, which was also integrated with a new ERP system. This now allows all production processes to be monitored in real time. All employees have access to all necessary information, such as production orders, plans, work instructions, etc., via tablets/PCs at any time. This has increased transparency and confirmed many positive effects: The effort and potential sources of error during handovers have been reduced, customers can receive information about the progress of orders at any time, and because processes were improved and problem areas verified, efficiency could be significantly increased and costs reduced. Lastly, real-time insight into material availability enabled digital production planning and thus increased production capacities.

The Right Funding

“Support from the consultants at Innovation Salzburg was extremely valuable for us in all these projects,” explains Johann Aster, Sales Manager at design composite. “This allowed us to apply for the right funding for every step of the process and thus jointly manage large investments.” This includes the resources needed for software, programming, human resources, and equipment, which were supported by the state funding Salzburg.Digital (specifically Digi-Invest) in this case.

About design composite

- Headquarters: Niedernsill

- 30 employees

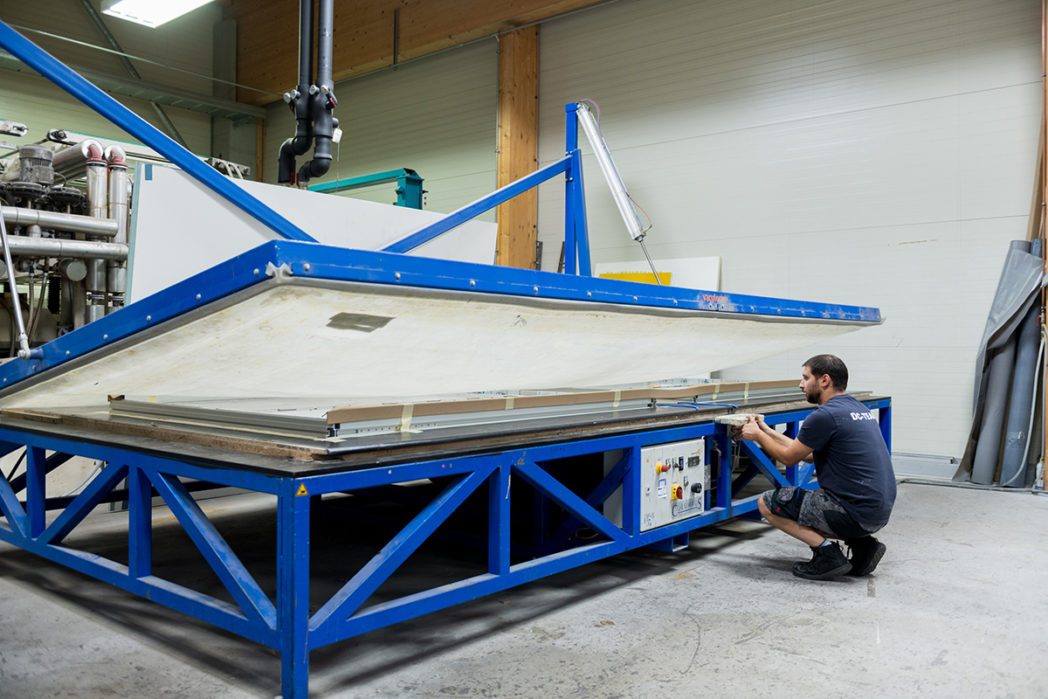

- Manufacturing of composite panels for commercial vehicles, industry, and construction, as well as architectural panels as design elements

- www.design-composite.com

This might also interest you

18. February 2026

SALZ 2026: A Festival for Innovation

How can companies remain competitive, innovative, and resilient in challenging times? SALZ – Festival for Innovation & Technology, together with the startup and investment conference SALT’N’VENTURE, will provide concrete answers on March 11, 2026, at Messezentrum Salzburg, bringing together industry, startups, and investors.

16. February 2026

Kick-off for the Salzburg Innovation Award

The WIKARUS – Salzburg Business Award will be presented every two years in the future. In the intervening years, the Salzburg Innovation Award will be announced, launching for the first time in 2026.

11. November 2025

Eleven Million Euros for Five New Research Centers

Salzburg is investing in research: around eleven million euros from EU and state funds will go toward establishing five new research and transfer centers. They cover key future-oriented topics: artificial intelligence, climate protection, health, tourism, and data security.

24. October 2025

Christian Doppler Laboratory unites Artificial Intelligence and Image Processing in Salzburg

Salzburg is strengthening its cutting-edge research: In the new Christian Doppler Laboratory for the Authentication of Persons and Object Surfaces, innovative solutions for enhanced security are being developed by combining artificial intelligence and image processing. These solutions are created in close collaboration between science and industry.